What are the Advantages of Capacitor Cabinet Products?

I. Introduction

In the realm of electrical engineering, capacitor cabinets play a pivotal role in enhancing the efficiency and reliability of power systems. These specialized enclosures house capacitor banks, which are essential for power factor correction—a process that optimizes the use of electrical power. As industries and commercial establishments strive for greater energy efficiency and sustainability, understanding the advantages of capacitor cabinet products becomes increasingly important. This article aims to explore the various benefits of capacitor cabinets, shedding light on their significance in modern electrical systems.

II. Understanding Capacitor Cabinets

A. Components of a Capacitor Cabinet

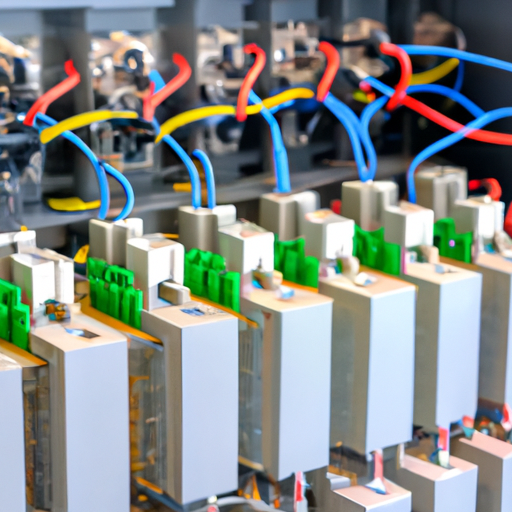

A capacitor cabinet is a comprehensive assembly that includes several key components:

1. **Capacitor Banks**: These are the heart of the cabinet, consisting of multiple capacitors connected in parallel or series to store and release electrical energy as needed.

2. **Control Systems**: These systems manage the operation of the capacitor banks, ensuring they engage and disengage based on the real-time power factor of the electrical system.

3. **Protection Devices**: To safeguard the system from faults and overloads, capacitor cabinets are equipped with various protection devices, such as fuses and circuit breakers.

B. Types of Capacitor Cabinets

Capacitor cabinets come in different configurations to meet specific needs:

1. **Fixed Capacitor Banks**: These are designed to provide a constant level of reactive power compensation, suitable for applications with stable load conditions.

2. **Automatic Capacitor Banks**: These systems dynamically adjust the level of reactive power compensation based on real-time demand, making them ideal for variable load conditions.

3. **Harmonic Filters**: These specialized cabinets not only provide power factor correction but also mitigate harmonic distortion in the electrical system, improving overall power quality.

III. Advantages of Capacitor Cabinet Products

A. Improved Power Factor

The power factor is a measure of how effectively electrical power is being converted into useful work output. A high power factor indicates efficient utilization of electrical energy, while a low power factor can lead to increased energy costs and penalties from utility companies. Capacitor cabinets improve the power factor by supplying reactive power, which reduces the burden on the electrical system and enhances overall efficiency.

B. Energy Efficiency

One of the most significant advantages of capacitor cabinets is their ability to enhance energy efficiency. By correcting the power factor, these cabinets reduce energy losses in the system, leading to lower electricity bills. Businesses can save substantial amounts on their energy costs, making capacitor cabinets a financially sound investment.

C. Voltage Regulation

Capacitor cabinets play a crucial role in stabilizing voltage levels within an electrical system. By providing reactive power support, they help prevent voltage drops that can occur during peak demand periods. This stabilization is vital for maintaining the performance of sensitive equipment and ensuring the reliability of electrical supply.

D. Enhanced Equipment Lifespan

Electrical equipment is subject to stress from voltage fluctuations and poor power quality. By improving the power factor and stabilizing voltage levels, capacitor cabinets reduce the strain on electrical devices. This leads to a longer lifespan for equipment, lower maintenance costs, and fewer unexpected breakdowns, ultimately contributing to operational efficiency.

E. Increased System Capacity

Capacitor cabinets allow businesses to increase their system capacity without the need for costly infrastructure upgrades. By optimizing the existing resources, companies can accommodate more load, which is particularly beneficial in industries experiencing growth or fluctuations in demand. This flexibility can be a game-changer for businesses looking to expand their operations.

F. Environmental Benefits

In an era where sustainability is paramount, capacitor cabinets contribute to reducing the carbon footprint of electrical systems. By improving energy efficiency and reducing losses, these cabinets help lower greenhouse gas emissions associated with electricity generation. Additionally, they support the integration of renewable energy sources, further promoting sustainable energy practices.

G. Flexibility and Scalability

Capacitor cabinets offer customization options to suit various applications, making them highly flexible. Whether for industrial, commercial, or renewable energy systems, these cabinets can be tailored to meet specific requirements. Furthermore, they can be easily integrated into existing systems, allowing for scalability as business needs evolve.

IV. Applications of Capacitor Cabinets

A. Industrial Settings

In manufacturing plants and heavy machinery operations, capacitor cabinets are essential for maintaining power quality and efficiency. They help manage the reactive power demands of large motors and equipment, ensuring smooth operations and reducing energy costs.

B. Commercial Buildings

Office complexes and retail spaces benefit from capacitor cabinets by improving energy efficiency and reducing operational costs. These systems help maintain stable voltage levels, which is crucial for the performance of lighting, HVAC systems, and other electrical devices.

C. Renewable Energy Systems

Capacitor cabinets are increasingly being used in renewable energy installations, such as wind farms and solar power systems. They help manage the reactive power generated by these sources, ensuring that the energy produced is effectively utilized and integrated into the grid.

V. Considerations When Choosing Capacitor Cabinets

When selecting capacitor cabinets, several factors should be considered:

A. Sizing and Capacity Requirements

It is essential to accurately assess the sizing and capacity requirements of the capacitor cabinet to ensure optimal performance. An undersized cabinet may not provide sufficient reactive power support, while an oversized one can lead to inefficiencies.

B. Type of Control System

The choice of control system—fixed or automatic—depends on the variability of the electrical load. Automatic systems are more suitable for applications with fluctuating demand, while fixed systems may suffice for stable loads.

C. Environmental Conditions

The operating environment can impact the performance and longevity of capacitor cabinets. Factors such as temperature, humidity, and exposure to corrosive elements should be considered when selecting a cabinet.

D. Compliance with Regulations and Standards

It is crucial to ensure that the chosen capacitor cabinet complies with relevant regulations and industry standards. This not only guarantees safety and reliability but also helps avoid potential legal issues.

VI. Conclusion

In summary, capacitor cabinet products offer a multitude of advantages that enhance the efficiency, reliability, and sustainability of electrical systems. From improving power factor and energy efficiency to extending equipment lifespan and providing environmental benefits, these cabinets play a vital role in modern electrical infrastructure. As businesses increasingly prioritize efficiency and sustainability, the adoption of capacitor cabinets is a strategic move that can lead to significant operational improvements and cost savings. Companies are encouraged to consider the integration of capacitor cabinets into their systems to harness these benefits and contribute to a more sustainable future.

VII. References

1. IEEE Standards Association. (2020). IEEE Std 18-2002 (Revision of IEEE Std 18-1992) - IEEE Standard for Shunt Power Capacitors.

2. National Electrical Manufacturers Association (NEMA). (2019). Capacitors for Power Factor Correction.

3. U.S. Department of Energy. (2021). Energy Efficiency and Renewable Energy: Power Factor Correction.

4. Various industry publications and articles on capacitor technology and applications.