What are the Latest Series Capacitors? What are the Procurement Models for Equipment Components?

I. Introduction

A. Definition of Series Capacitors

Series capacitors are electrical components that store energy in an electric field, created by a voltage difference across their terminals. When connected in series with a load, they can improve the performance of electrical systems by enhancing voltage stability, reducing losses, and improving power factor. These capacitors are essential in various applications, from power electronics to renewable energy systems.

B. Importance of Series Capacitors in Electrical Systems

In modern electrical systems, series capacitors play a crucial role in managing power quality and efficiency. They help mitigate voltage fluctuations, reduce harmonic distortion, and enhance the overall reliability of power delivery. As the demand for efficient energy solutions grows, the significance of series capacitors becomes increasingly apparent.

C. Overview of the Article's Focus

This article will explore the latest developments in series capacitors, including technological advancements, types, and applications. Additionally, we will discuss procurement models for equipment components, highlighting the challenges and future trends in this dynamic field.

II. Latest Developments in Series Capacitors

A. Technological Advancements

1. Materials Used in Capacitor Manufacturing

Recent advancements in materials science have led to the development of high-performance dielectric materials, such as polypropylene and polyester films, which enhance the efficiency and reliability of series capacitors. These materials offer improved thermal stability and lower losses, making them ideal for high-frequency applications.

2. Innovations in Design and Efficiency

Innovative designs, such as multilayer capacitors and hybrid configurations, have emerged to meet the growing demands for compactness and efficiency. These designs allow for higher capacitance values in smaller packages, making them suitable for applications in space-constrained environments.

B. Types of Series Capacitors

1. Film Capacitors

Film capacitors are known for their excellent stability and low loss characteristics. They are widely used in power electronics and renewable energy systems due to their ability to handle high voltages and currents.

2. Ceramic Capacitors

Ceramic capacitors are favored for their small size and high capacitance-to-volume ratio. They are commonly used in consumer electronics and automotive applications, where space and weight are critical factors.

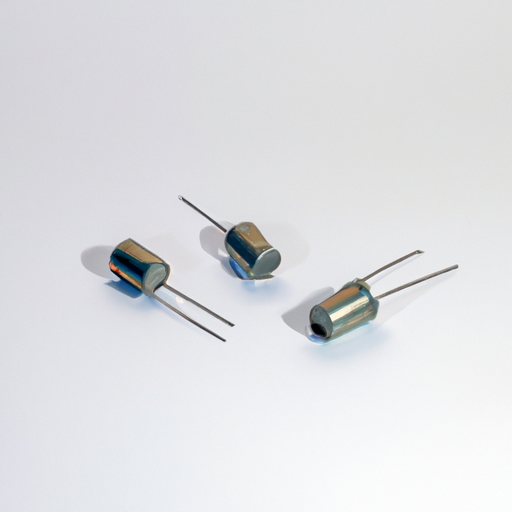

3. Electrolytic Capacitors

Electrolytic capacitors are known for their high capacitance values and are often used in power supply circuits. However, they have limitations in terms of voltage ratings and temperature stability compared to film and ceramic capacitors.

C. Applications of Latest Series Capacitors

1. Power Electronics

In power electronics, series capacitors are used to improve the efficiency of converters and inverters, enabling better performance in applications such as motor drives and renewable energy systems.

2. Renewable Energy Systems

With the rise of renewable energy sources, series capacitors are essential for managing power quality and stability in solar and wind energy systems. They help mitigate voltage fluctuations and enhance grid integration.

3. Electric Vehicles

In electric vehicles (EVs), series capacitors are used in power management systems to improve energy efficiency and extend battery life. They play a vital role in regenerative braking systems, where they store energy during braking and release it during acceleration.

4. Industrial Automation

In industrial automation, series capacitors are employed in various applications, including motor control and power factor correction, to enhance system efficiency and reliability.

III. Key Features of Modern Series Capacitors

A. Enhanced Performance Metrics

1. Voltage Ratings

Modern series capacitors are designed to handle higher voltage ratings, making them suitable for demanding applications in power electronics and renewable energy systems.

2. Capacitance Values

Advancements in materials and design have led to increased capacitance values, allowing for more compact solutions without sacrificing performance.

3. Temperature Stability

Improved thermal stability ensures that modern series capacitors can operate effectively in a wide range of temperatures, enhancing their reliability in various environments.

B. Reliability and Longevity

1. Failure Rates

The latest series capacitors exhibit lower failure rates due to advancements in manufacturing processes and quality control measures. This reliability is crucial for applications where downtime can result in significant costs.

2. Maintenance Considerations

With improved longevity, modern series capacitors require less frequent maintenance, reducing operational costs and enhancing system reliability.

C. Environmental Considerations

1. RoHS Compliance

Many manufacturers are now producing series capacitors that comply with the Restriction of Hazardous Substances (RoHS) directive, ensuring that they are environmentally friendly and safe for use.

2. Recycling and Sustainability

The industry is increasingly focusing on sustainability, with many manufacturers implementing recycling programs for end-of-life capacitors, reducing waste and promoting a circular economy.

IV. Procurement Models for Equipment Components

A. Overview of Procurement Models

1. Traditional Procurement

Traditional procurement involves a straightforward purchasing process, where buyers source components from suppliers based on established relationships and contracts. This model is often characterized by longer lead times and less flexibility.

2. Just-In-Time (JIT) Procurement

JIT procurement aims to reduce inventory costs by ordering components only as needed. This model requires close collaboration with suppliers to ensure timely delivery and minimize stockouts.

3. E-Procurement

E-procurement leverages digital platforms to streamline the purchasing process, allowing for greater efficiency and transparency. This model enables buyers to compare prices, track orders, and manage supplier relationships more effectively.

B. Factors Influencing Procurement Decisions

1. Cost Considerations

Cost is a primary factor in procurement decisions. Buyers must balance the need for high-quality components with budget constraints, often seeking competitive pricing without compromising performance.

2. Supplier Reliability

Supplier reliability is critical in ensuring timely delivery and consistent quality. Buyers often evaluate suppliers based on their track record, financial stability, and ability to meet specifications.

3. Lead Times and Availability

Lead times and component availability are essential considerations, especially in industries where delays can impact production schedules. Buyers must assess suppliers' capabilities to meet their timelines.

C. Strategic Sourcing

1. Supplier Relationships

Building strong relationships with suppliers can lead to better pricing, improved service, and enhanced collaboration on product development.

2. Risk Management

Effective risk management strategies are essential in procurement, particularly in volatile markets. Buyers must assess potential risks, such as supply chain disruptions, and develop contingency plans.

3. Quality Assurance

Ensuring quality is paramount in procurement. Buyers must implement rigorous quality assurance processes to verify that components meet specifications and performance standards.

V. Challenges in Procurement of Series Capacitors

A. Market Volatility

The capacitor market can be volatile, with fluctuations in demand and supply affecting pricing and availability. Buyers must stay informed about market trends to make informed procurement decisions.

B. Supply Chain Disruptions

Global supply chain disruptions, exacerbated by events such as the COVID-19 pandemic, have highlighted the need for resilient procurement strategies. Buyers must develop contingency plans to mitigate the impact of disruptions.

C. Technological Obsolescence

Rapid advancements in technology can lead to obsolescence of certain capacitor types. Buyers must stay updated on industry trends to ensure they are sourcing the latest and most relevant components.

VI. Future Trends in Series Capacitors and Procurement Models

A. Emerging Technologies

1. Smart Capacitors

The development of smart capacitors, which integrate sensors and communication capabilities, is on the rise. These capacitors can provide real-time data on performance and health, enabling proactive maintenance and improved system management.

2. Integration with IoT

The integration of series capacitors with the Internet of Things (IoT) is expected to enhance their functionality and performance. IoT-enabled capacitors can communicate with other devices, providing valuable insights for system optimization.

B. Evolving Procurement Strategies

1. Digital Transformation in Procurement

The digital transformation of procurement processes is set to continue, with increased automation and data analytics driving efficiency and decision-making.

2. Sustainability in Sourcing

Sustainability will play a more significant role in procurement strategies, with buyers increasingly prioritizing environmentally friendly products and practices.

VII. Conclusion

A. Summary of Key Points

In summary, series capacitors are vital components in modern electrical systems, with recent advancements in technology and materials enhancing their performance and reliability. Understanding the latest developments and procurement models is essential for industry professionals to make informed decisions.

B. The Importance of Staying Updated on Capacitor Technology and Procurement Models

As technology continues to evolve, staying updated on the latest trends in series capacitors and procurement models is crucial for maintaining a competitive edge in the industry.

C. Call to Action for Industry Professionals

Industry professionals are encouraged to engage with suppliers, invest in training, and adopt innovative procurement strategies to navigate the challenges and opportunities in the capacitor market effectively.

VIII. References

A. Academic Journals

- Journal of Electrical Engineering

- IEEE Transactions on Power Electronics

B. Industry Reports

- Market Research Reports on Capacitor Technologies

- Renewable Energy Systems Analysis

C. Manufacturer Specifications and White Papers

- Manufacturer Technical Documents

- White Papers on Capacitor Innovations

---

This blog post provides a comprehensive overview of the latest developments in series capacitors and the various procurement models for equipment components, offering valuable insights for industry professionals.